- somkeat.k@63-plus.com

- 345/148 Moo 3, Surasak Subdistrict, Sriracha District, Chonburi Province 20110

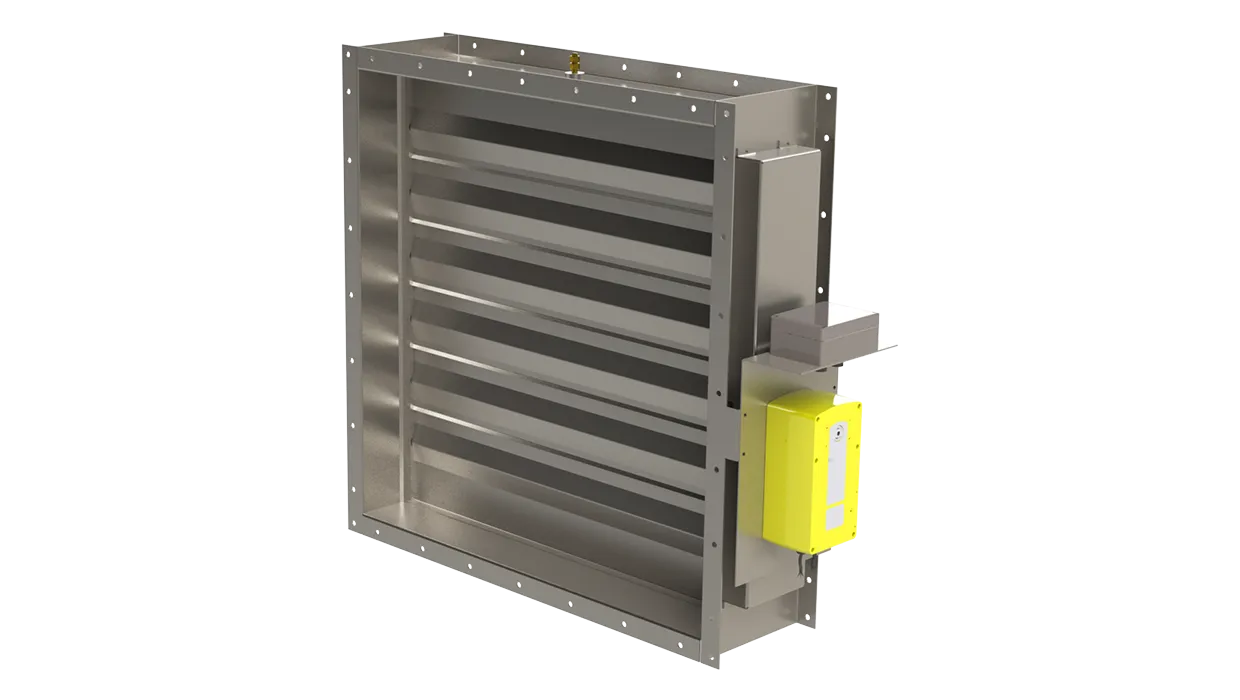

Halton Ivo ITR – Pressure relief damper

Non Return and Pressure Relief Dampers

Overview

The Halton Ivo ITR pressure relief damper, a reliable evolution of the EI120S fire damper, is marked and tested according to its respective standards. It is fire-resistant and provides insulation with low smoke leakage. In normal mode, it is closed, and opens in an extinguishing situation to release excess pressure. This product can be installed horizontally or vertically in concrete, masonry, and lightweight structures, providing a reliable solution for your safety needs.

Application areas

- Buildings

- IT facilities

- Archives

Key features

- All units are factory tested to guarantee performance

- Operating pressure 6 bar (factory setting)

- Supply pressure max. 60 bar

- Closing pressure 300 Pa

- Actuator ATEX certified

- The structure is based on a CE-marked fire damper

- Sizes available from 200x200 mm up to 1000x800 mm

- Designed for use with gas extinguishing systems

- Suitable for use in demanding conditions

Operating principle

The pressure relief damper Halton Ivo ITR, based on the EI120 fire damper, is a reliable unit equipped with a pneumatic actuator and pressure reducer. Upon activation of the gas extinguishing system, the pneumatic actuator opens the damper, reducing the pressure level inside the room. Once the pressure is balanced, the spring inside the pneumatic actuator closes the damper, demonstrating its dependable functionality.

- The pressure relief damper is closed in normal mode and opens in an extinguishing situation to remove excess pressure from space.

- After the extinguishing situation, the pressure relief damper closes to the closed position with the help of a mechanical spring.

- Halton recommends performing a functional test of the gas extinguishing system before commissioning the premises.

This pressure relief damper is a vital part of the automatic gas extinguishing system to release excess gas from space and to avoid any damage to building construction due to high pressure. IT facilities and special facilities such as archives use gas extinguishing systems. These facilities can cause severe consequences by damaging data and assets. The interruption of operations or destruction of assets are potential outcomes. Hence, these automatic gas extinguishing systems, which extinguish gases such as argon, other inert gases, CO2 , and Novec, often protects such facilities.

Features and options

| Feature | Description |

|---|---|

| Pneumatic actuator | Spring return and pressure reducer |

| Size | 200x200 - 1000x800 mm |

| Weight | 7 - 26 kg |

| Pressure difference in ducts | 1200 Pa |

| Integrated installation frame | Galvanised steel (Stainless steel option available) |

Structure and materials

Fig. 1. Halton Ivo ITR structure

| No. | Part | Material | Note |

|---|---|---|---|

| 1 | Blade | Asbestos free boards made of mineral fiber | - |

| 2 | Operating model (actuator) | - | Pneumatic, including pressure reducer. |

| 3 | Inspection hatch covering | Galvanised steel | Stainless steel, when casing also stainless |

| 4 | Casing | Galvanised steel | Stainless steel options available on request |

Dimensions and weight

Fig. 2. Halton Ivo ITR dimensions

| W [mm] | H [mm] |

|---|---|

| 200, 250, 300, 350, 400, 450, 500, 550, 600, 700, 800, 900, 1000 | 200, 250, 300, 350, 400, 450, 500, 550, 600, 700, 800 |

Weight [kg]

| H [mm] | W [mm] | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 700 | 800 | 900 | 1000 | |

| 200 | 7.1 | 7.6 | 8.1 | 9.1 | 9.6 | 10.1 | 10.6 | 11.1 | 11.6 | 13.1 | 14.1 | 15.6 | 16.6 |

| 250 | 8.1 | 8.6 | 9.1 | 10.1 | 10.6 | 11.1 | 11.6 | 12.6 | 13.1 | 14.1 | 15.6 | 17.1 | 18.1 |

| 300 | 8.6 | 9.1 | 10.1 | 10.6 | 11.1 | 12.1 | 12.6 | 13.6 | 14.1 | 15.6 | 17.1 | 18.1 | 19.6 |

| 350 | 9.6 | 10.1 | 11.1 | 12.1 | 12.6 | 13.6 | 14.1 | 15.1 | 15.6 | 17.1 | 18.6 | 20.1 | 21.6 |

| 400 | 10.1 | 11.1 | 11.6 | 12.6 | 13.6 | 14.1 | 15.1 | 15.6 | 16.6 | 18.1 | 20.1 | 20.6 | 23.1 |

| 450 | 10.6 | 11.6 | 12.6 | 13.6 | 14.1 | 15.1 | 16.1 | 16.6 | 17.6 | 19.6 | 21.1 | 23.1 | 24.6 |

| 500 | 11.1 | 12.1 | 13.1 | 14.1 | 15.1 | 16.1 | 17.1 | 17.6 | 18.6 | 21.1 | 22.6 | 24.1 | 26.1 |

| 550 | 12.1 | 13.1 | 14.1 | 15.1 | 16.1 | 17.1 | 17.6 | 18.6 | 19.6 | 22.6 | 23.6 | 25.6 | - |

| 600 | 12.6 | 13.6 | 14.6 | 15.6 | 16.6 | 17.6 | 18.6 | 19.6 | 21.1 | 24.1 | 25.1 | - | - |

| 700 | 13.6 | 15.1 | 16.1 | 17.6 | 18.6 | 19.6 | 20.6 | 22.1 | 23.1 | - | - | - | - |

| 800 | 15.1 | 16.1 | 17.6 | 19.1 | 20.1 | 21.1 | 22.6 | 23.6 | 25.1 | - | - | - | - |

(-) = size not available

Specification

The pressure relief damper Halton Ivo ITR, based on the EI120 fire damper, is a reliable unit equipped with a pneumatic actuator and pressure reducer. Its structure is based on a CE-approved fire damper and ATEX-approved actuator. It is tested according to CE certification standards EN15650 and EN 1366-2 for fire testing as a fire damper.

Construction

- The in-wall installation allows for the installation of the spindle of the blade at any position (360°).

- In concrete, masonry and lightweight structures, you can install fire dampers in both vertical and horizontal positions.

- Leakage through closed damper blade fulfils EN 1751 class 2

- The casing complies with the tightness requirements for EN 1751 class C. According to EN 1751, leakage through a closed damper blade fulfils class 2.

- It can be installed away from the separate element up to 1.0 metre, fulfilling fire resistance classes up to EI 90 (ve ho i <-> o) S.

- A maximum fire resistance class EI 120 (ve ho i↔o) S requirements.

Material

- The casing complies with the tightness requirements for EN 1751 class C. According to EN 1751, leakage through a closed damper blade fulfils class 2.

- Galvanised or stainless steel (AISI 316L) casing, with the blade made of fire-resistant and asbestos-free boards (mineral fibre).

- Equipped with one inspection hatch, which allows you to check the position of the damper blade.

Standards

There is no harmonized product standard for pressure relief dampers.

The structure of this damper is based on for CE-approved fire damper and ATEX-approved actuator, with the exception that this is opened with inert gas release (extinguishing gas displaces oxygen) in connection with overpressure to lead away.

Complies with ventilation of building standard EN 15650 (CE)

The basis of this product complies with the following standards:

| Performance/processes | Standard |

|---|---|

| Fire classification (EI 120 (ve hoi↔o) S,

EI 90 (ve ho i↔o) S, EI 60 (ve ho i↔o) S) |

EN 13501-3+A1 standard |

| Fire testing | EN 1366-2 |

| Construction Products Regulation (CPR) | 1391-CPR-2018/0202 |

|

Declaration of Performance (DoP) |

10034-ESR-2019/01/01 |

| Leakage through closed damper blade fulfils class 2 | EN 1751 |

| Damper casing tightness class C | EN 1751 |

| Corrosion resistance (Salt mist test) | EN 60068-2-52 |